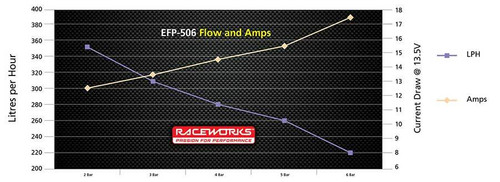

Raceworks 310LPH @ 3Bar (13.5V) fuel pump. For flow details at and current draw 13.5V please consult chart below. 044 Equivalent, 60.5mm Pump Diameter, External Check Valve.

Raceworks has developed a range of high-volume in-tank and external fuel pumps to suit the most demanding street and track requirements. Whether your engine is high boost or high-capacity; you can rely on Raceworks High Performance Fuel Pumps to provide ample fuel volume at up to 6bar of line pressure. Raceworks in-tank pumps are designed to replicate factory fitment in a wide range of OE modules allowing faster installation, and are all supplied with strainers and wiring tails, making a hassle-free upgrade for any vehicle.

All Raceworks products come with a 2 year warranty.

Features:

- Raceworks 044 Style

- 310 LPH @ 3Bar

- 11A @ 3Bar Current Draw

- Ext Check Valve

- Inlet – M18x1.5

- Outlet – M12x1.5

Compatible Inlet Fittings:

- Female AN-8 Swivel – RWF-906-08-M18BK

- 5/16” Barb – RWF-414-M18-05BK

- 3/8” Barb – RWF-414-M18-06BK

- 1/2” Barb – RWF-414-M18-08BK

- 5/8” Barb – RWF-414-M18-10BK/RWF-417-M18-10BK

- AN-6 Male Flare – RWF-734-06BK

- AN-8 Male Flare – RWF-734-08BK

- AN-10 Male Flare – RWF-734-10BK (*Recommended)

- AN-12 Male Flare – RWF-734-12BK (*Recommended)

- Intank Strainer Kit – FSA-094

Compatible Outlet Fittings:

USING INCLUDED CHECK VALVE

- AN-6 Male Flare Banjo Kit – RWF-724-044-06BK

- AN-8 Male Flare Banjo Kit – RWF-724-044-08BK

- 5/16” Barb Banjo Kit – RWF-807-044-05BK

- 3/8” Barb Banjo Kit – RWF-807-044-06BK

USING HIGH FLOW INLINE CHECK VALVE

- AN-6 Male Flare – RWF-612-06BK (*Recommended)

- AN-8 Male Flare – RWF-612-08BK (*Recommended)

USING NO CHECK VALVE

- AN-6 Male Flare Adapter – RWF-731-06BK

- AN-8 Male Flare Adapter – RWF-731-08BK

- AN-10 Male Flare Adapter – RWF-731-10BK

- 5/16” Barb Adapter – RWF-414-M12-05BK

- 3/8” Barb Adapter – RWF-414-M12-06BK

- 1/2” Barb Adapter – RWF-414-M12-08BK

- Banjo Bolt – RWF-724-06ABK

WHAT IS A CHECK VALVE?

Also known as a One-Way Valve, a Check Valve allows flow in one direction only, and prevents back flow (reverse flow). This is important when staging fuel pumps, or running multiple fuel pumps in the case of a pump failure. It also ensures that fuel pressure in the line is maintained, allowing the engine to start faster even if the fuel system has not been sufficiently primed.

FLYWHEEL POWER FIGURES (ESTIMATED)

Normally Aspirated Gasoline 850HP 635KW

Forced Inducted Low Boost Gasoline 690HP 515KW

Forced Inducted High Boost Gasoline 650HP 485KW